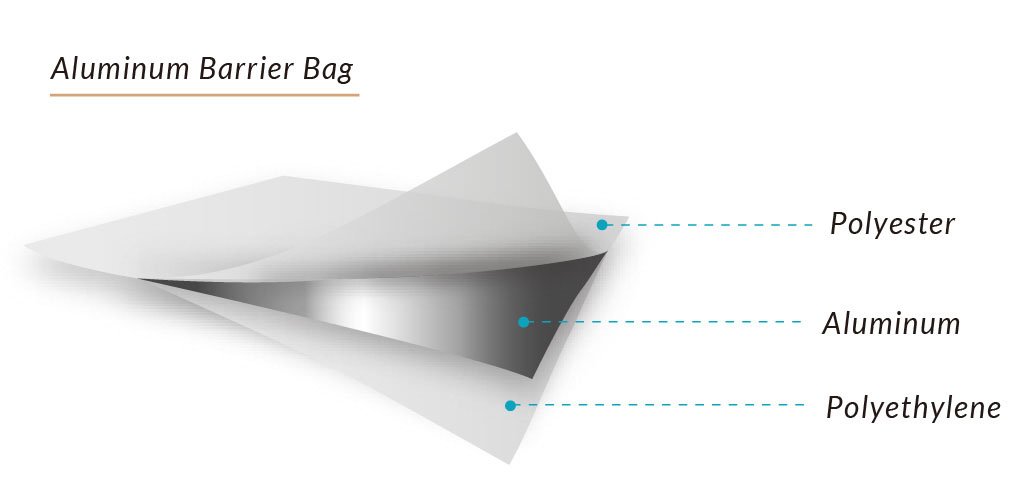

Aluminum Foil Barrier Bag

Product Introduction :

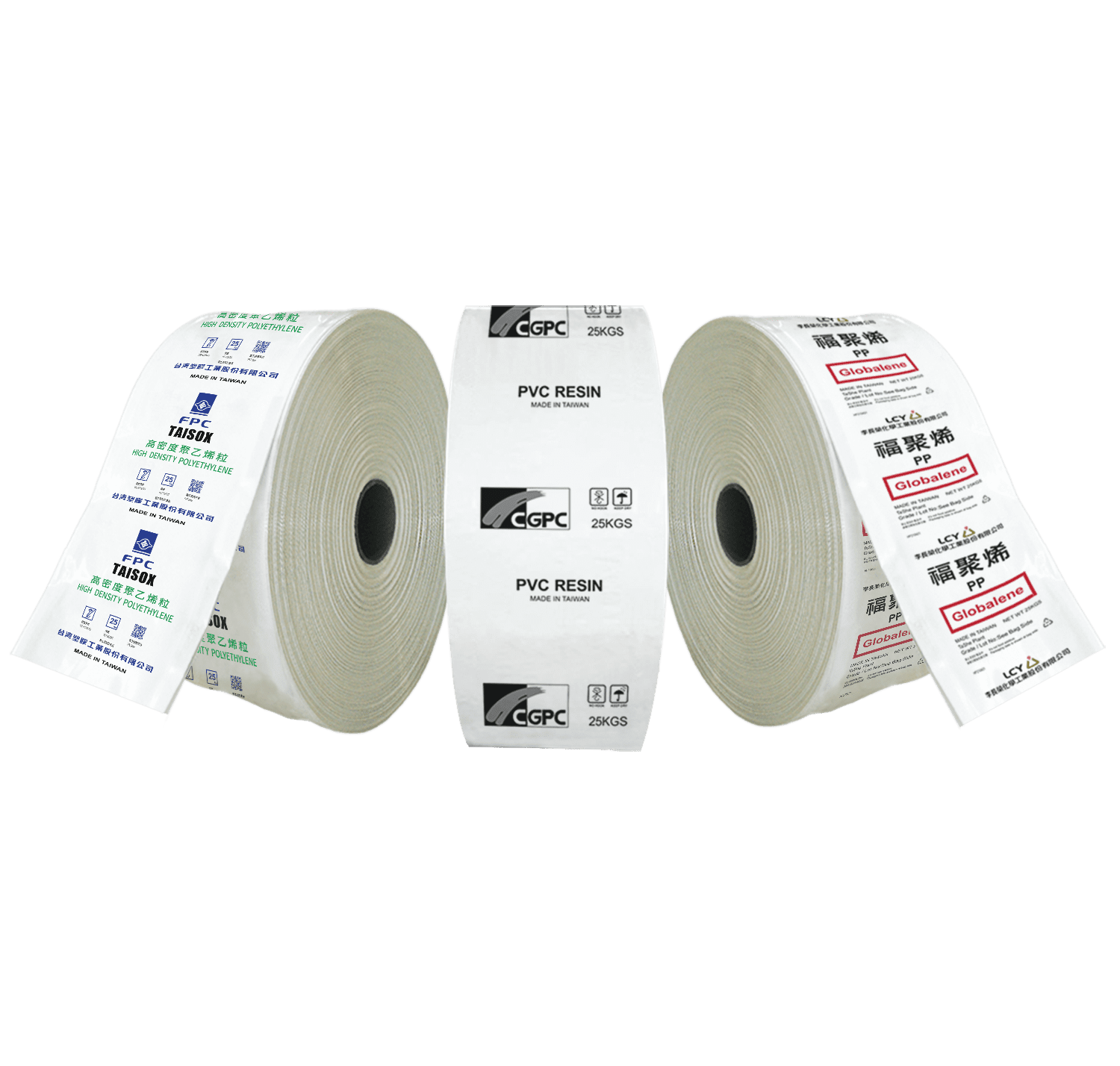

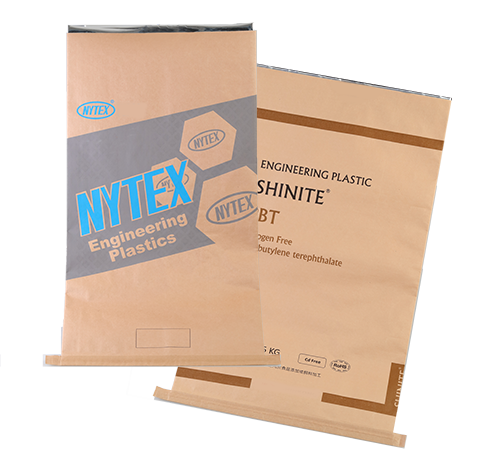

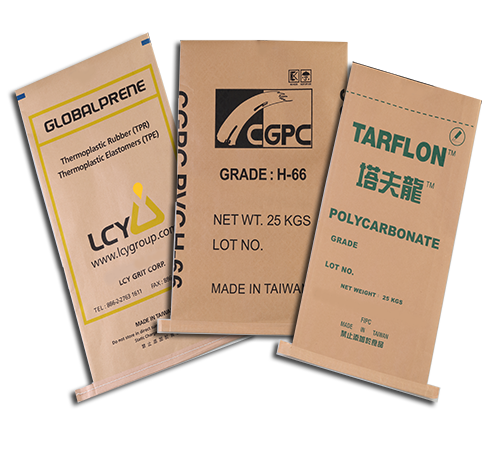

Aluminum-plastic composite barrier bag is the newest innovation in heavy-duty packaging; manufactured by laminating plastic film with aluminum to create bags that are moisture-proof, leak-proof, and block any lighting from penetrating through. These bags allow for beautifully printed exteriors to create high-quality packaging appearance. They also allow for one-way degassing and vacuuming, highly recommended for materials that cannot have moisture and high-value products.

※Applicable to food use: Coffee beans, ground coffee, biotech material

※Applicable to industrial use: Engineering plastics, NYLON materials, TPU materials, biodegradable plastic materials

Aluminum Foil Barrier Bag

Specification

| Length: | 50~110 cm |

| Width: | 35~60 cm |

| Printing : | 1~6 colors |

| Loading Capacity: | ≦ 25 kg |

| Anti-slip Treatment: | Static Friction Coefficient > 0.6 |

| Ink: | comply with Restriction of Hazardous Substance (RoHS) inspection standard |

| Bag Material: | comply with “ Sanitation Standard for Food Utensils, Containers and Packages” |

Customizing Options

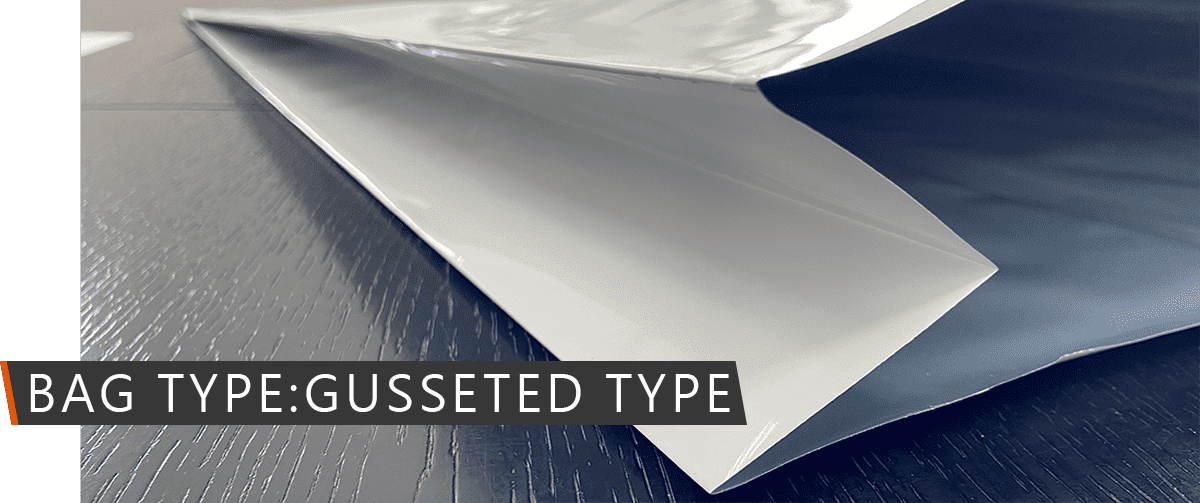

| ◎Bag Type:Flat type / Gusseted type | |

| ◎K-Seal bottom | |

| ◎Radius treatment | |

| ◎One-way degassing valve | |

| ◎UN Certificate |

Product Feature

| 1. Bag Type: | |

| Gusseted type |

| 2. K-Seal bottom: | |

| When filled, the pack stands up and appears more rectangular and voluminous. |

| 3. Radius treatment: | |

| safe for employees during stacking and transporting the bags. |

| 4. One-way degassing valve | |

| Patented specialized structure to exhaust air quickly from bags during packaging to increase efficiency. |