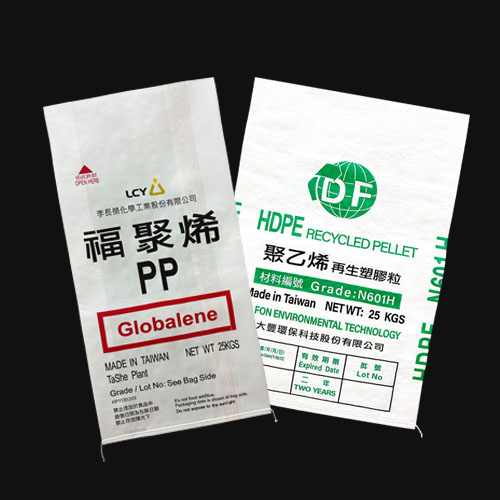

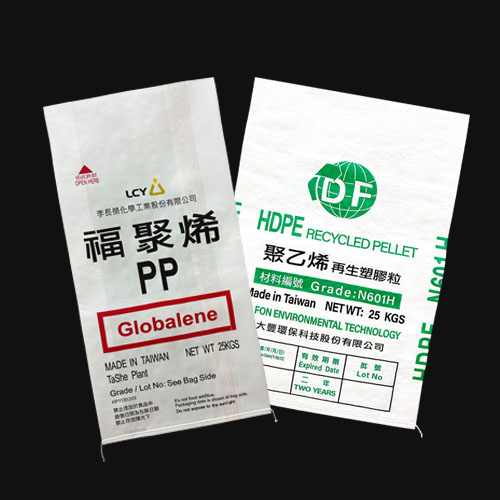

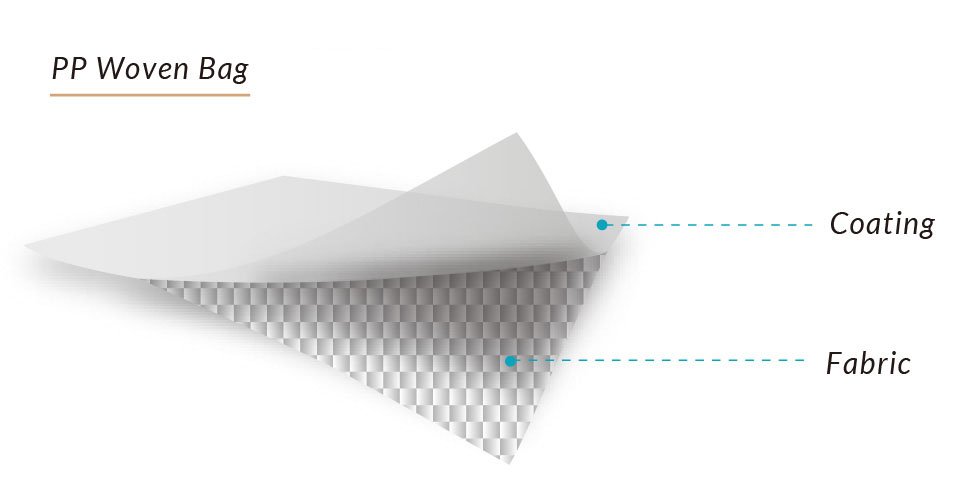

PP Woven Bag

Product Introduction :

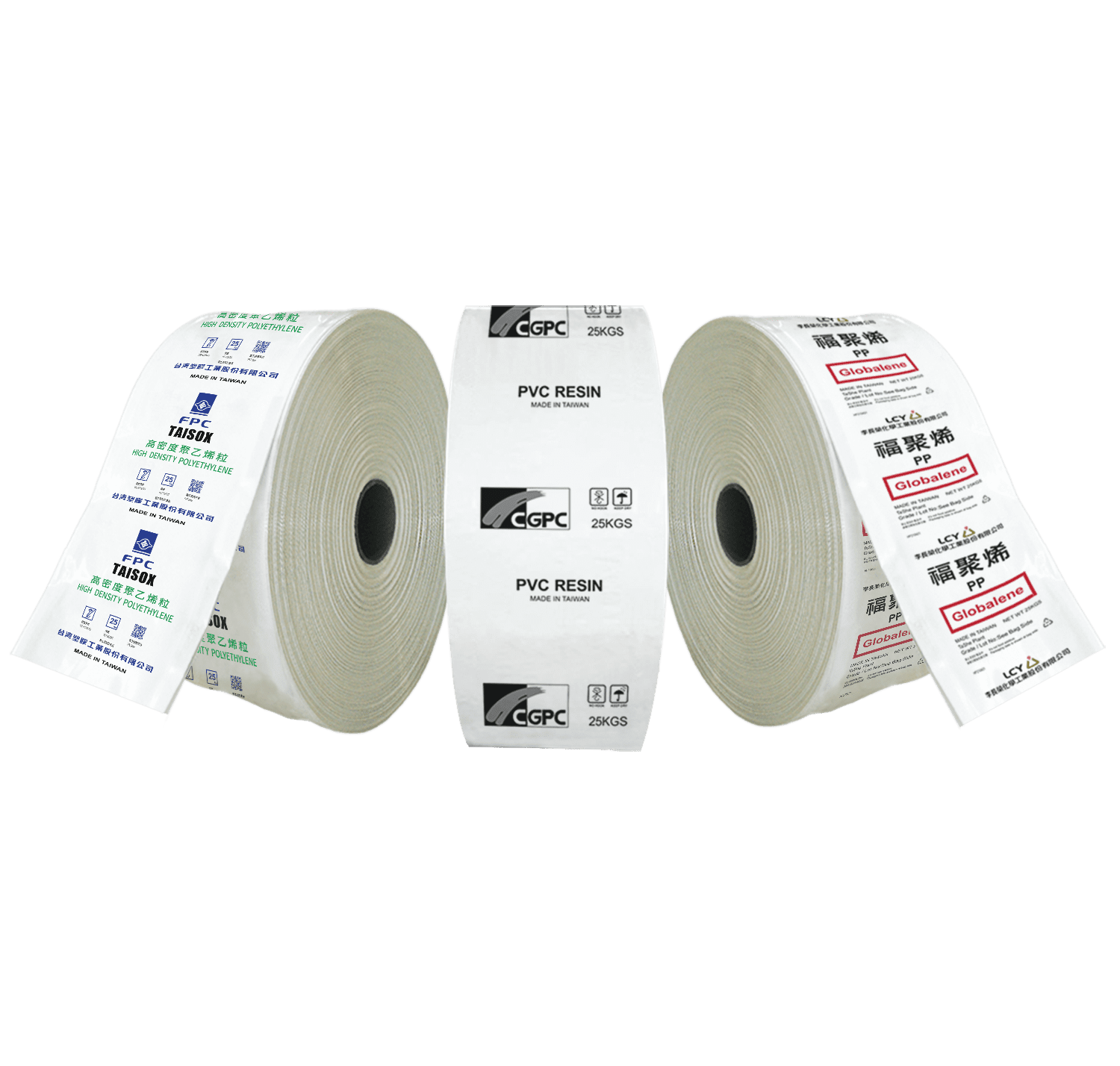

PP (polypropylene) woven bags are produced by interweaving polypropylene (PP) tapes into fabric and are known for their tensile strength and durability. After the coating is applied to the fabric, these bags are leak-proof and water-resistant, and can replace the traditional non-coated woven bag with inner bag.

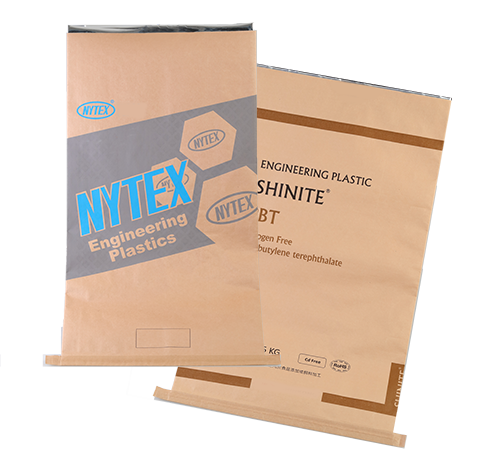

※Applicable to food use: Rice, flour, sugar, salt

※Applicable to industrial use: Plastic materials, chemical raw material, fertilizer, animal feed

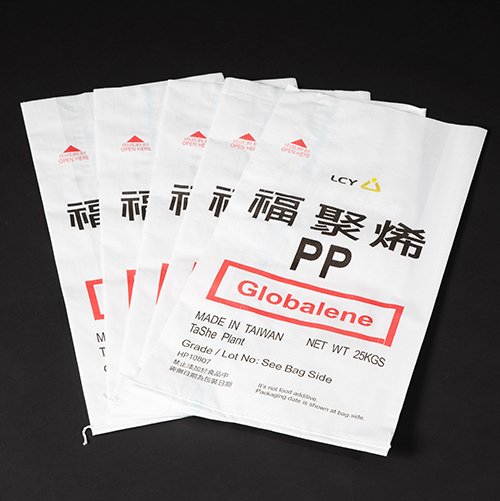

PP Woven Bag

Specification

| Category: | Non /Outer/Inner Coated PP Woven Bag |

| Length: | 58~130 cm |

| Width: | 40~70 cm |

| Printing : | 1~6 colors |

| Loading Capacity: | ≦ 50 kg |

| Anti-slip Treatment: | Static Friction Coefficient > 0.5 |

| Ink: | comply with Restriction of Hazardous Substance (RoHS) inspection standard |

| Bag material: | comply with “ Sanitation Standard for Food Utensils, Containers and Packages” |

Customizing Options

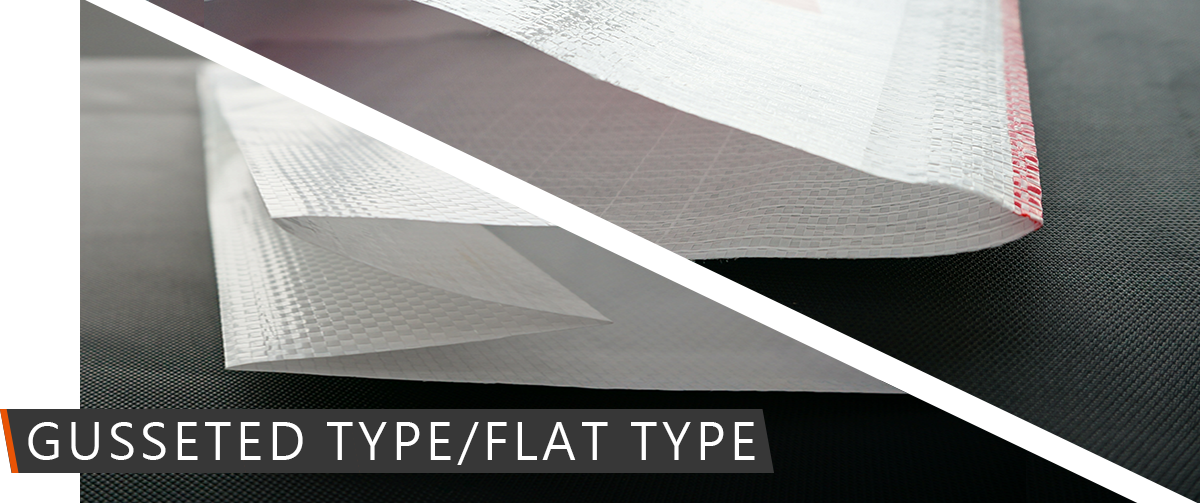

| ◎Bag Type:Flat type / Gusseted type | |

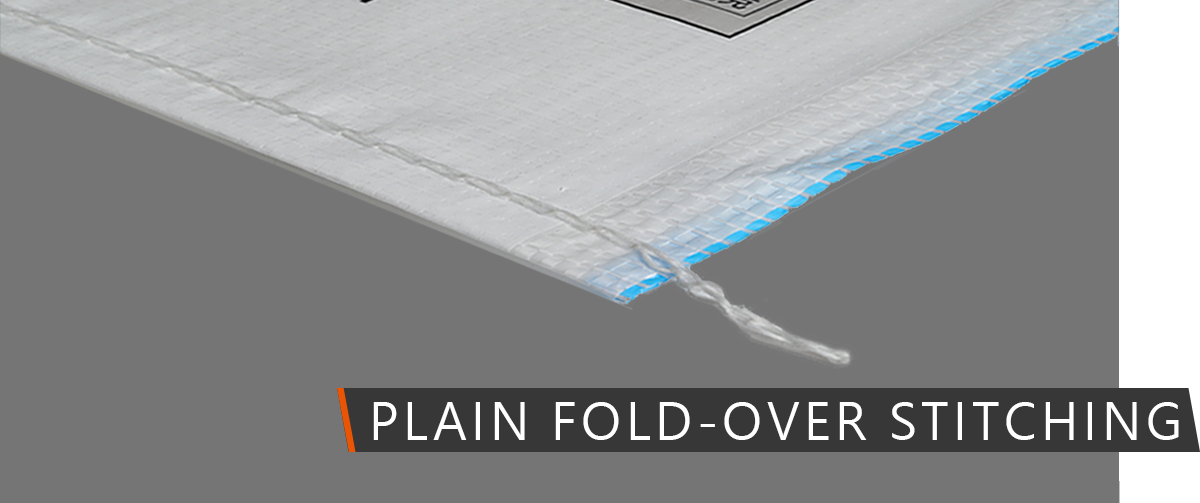

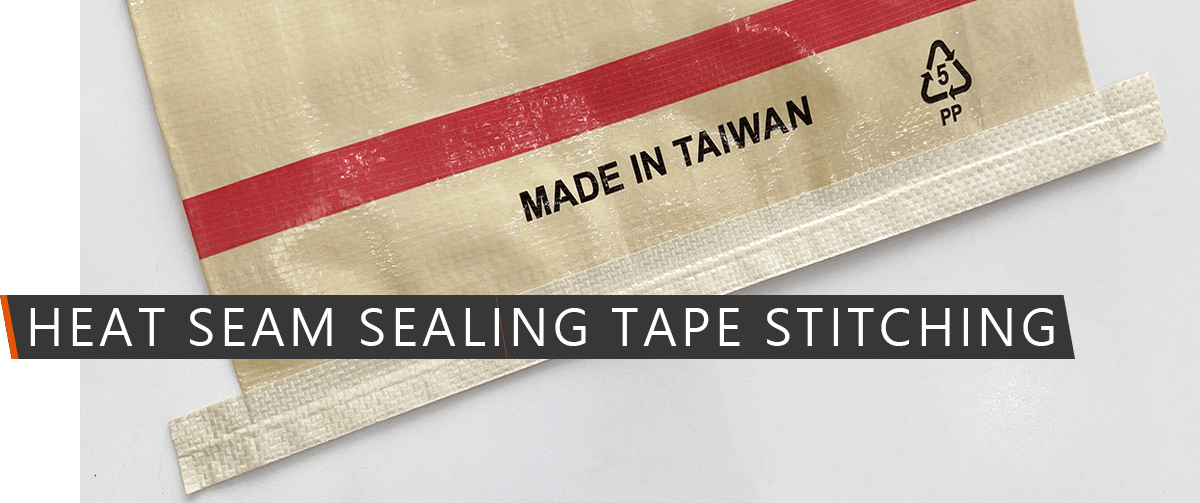

| ◎Bag Bottom Stitching: -Plain fold-over stitching -Fold-over stitching with PE tape -Heat seam sealing tape stitching(Over-Tape) | |

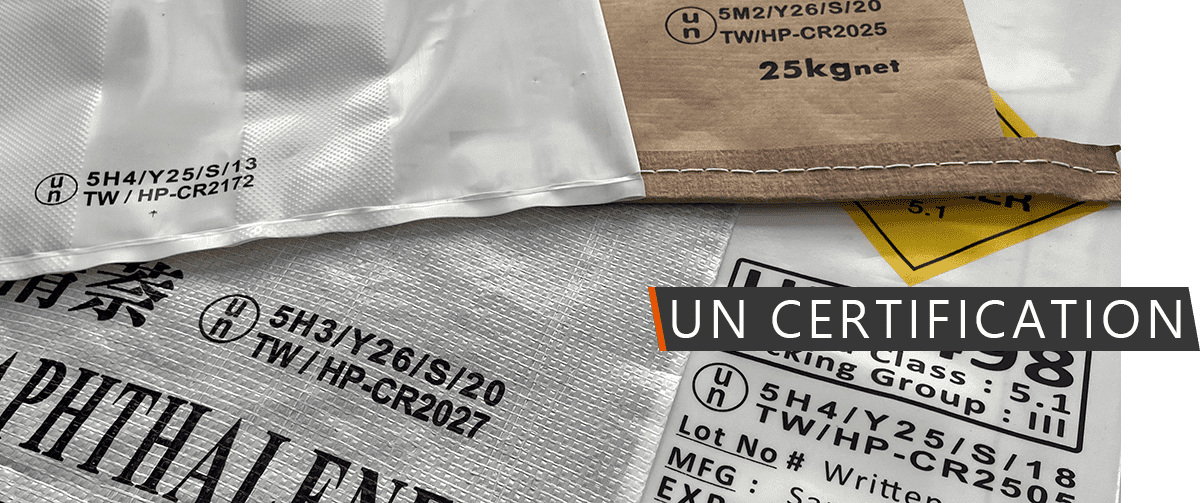

| ◎UN Certificate |

Product Feature

| 1. Bag Type: | |

| Flat type / Gusseted type |

| 2. Stitching: | |

| Stitch close bag bottom with high strength polyester cotton threads to increase load capacity. |

| 3. Heat Seam Sealing Tape Stitching(Over-Tape): | |

| Heat seam sealing tapes are multilayered adhesive films applied to the polyester cotton thread-sewn seams to prevent water from leaking through those seams. This creates a seamless exterior. |

| 4. UN Certificate: | |

| Comply with International Maritime Dangerous Goods (IMDG) Code inspection standard and apply UN certification for client’s bags. |